Facilities

At our state-of-the-art facility, we combine advanced technology with a commitment to quality to deliver products that set new industry standards.

Fabrication and Machining

One Haas TM-3P CNC Milling Machine : High-precision milling capabilities for a wide range of materials. Manufacturing complex parts, molds and custom components.

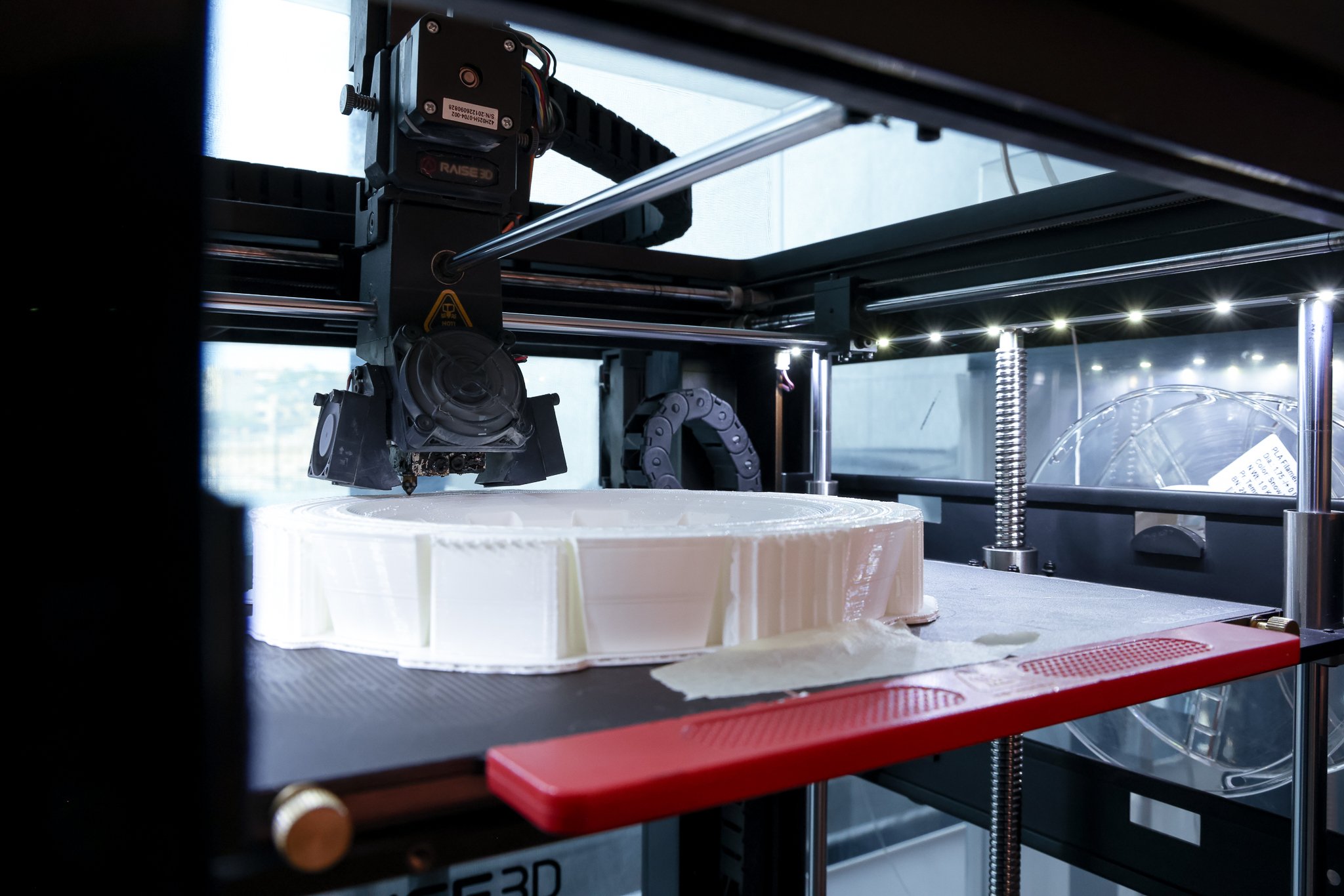

3D Printing and Additive Manufacturing

Latest generation 3D printing technology for fast production and superior material compatibility.

- Three Raise Pro2 3D Printers : Reliable and high-quality 3D printing for prototyping and small-scale production.

- Five Raise Pro2 Plus 3D Printers: Advanced large-format printing for detailed and durable large components.

- One Raise Pro3 3D Printer: Latest generation 3D printing technology for fast production and superior material compatibility.

Composite Manufacturing

Latest generation 3D printing technology for fast production and superior material compatibility.

- TurboHeat Composite Autoclave (1.2m x 3m): Compact autoclave for precision-curing of smaller composite parts.

- Italmatic Composite Autoclave (2.4m x 5m): Large-scale autoclave capable of curing large panels, vehicle bodies and aerospace components.

- Walk-In Freezer for Prepreg Storage: Temperature-controlled storage to maintain the integrity of composite prepreg materials.

- Two Blackman & White 1.6M Versa-Tech Cutting Tables: Precision cutting of fabrics, prepregs, and other materials to exact specifications of fabric direction and shape, automatic nesting optimization, labeling for kitting.

Painting and Finishing

Four AMT Downdraft Paint Booths: Advanced painting and finishing capabilities for vehicles, parts and assemblies, ensuring durability and aesthetic excellence.